Case Study - 'BIM 360 Glue'

Urbanest Darling Square is a two stage multi-unit student accommodation development. It comprises of two 22 story towers, a link bridge, and large communal spaces. Tower 1, known as DS1 was stage 1, and Tower 2 (DS2) and the link are stage 2. Northrop Sydney was engaged to provide structural engineering services. We used Autodesk Revit to enhance the design process and to document the entire project.

During construction of DS1 Buildcorp experienced cost overruns in the supply of reinforcing steel for all concrete elements, and time delays driven by on site building services coordination. For DS2 Buildcorp and Northrop were looking towards emerging technology to alleviate the cost and time overruns experienced during stage 1.

Autodesk BIM 360 Glue is a cloud based collaboration tool for the AEC industry, it provides all the clash detection tools of Navisworks in a far more collaborative environment. The iterative design cycle is dramatically sped up in comparison to collaborating in other BIM platforms. Buildcorp mandated the use of BIM360 glue for all design consultants, this allowed the design team the ability to build the project digitally to fully coordinate all elements long before clashes became an issue on site. Northrop are fully engaged with the process, taking the level of development of the structural model far beyond what would be delivered in the traditional design process, to ensure a positive outcome for the project.

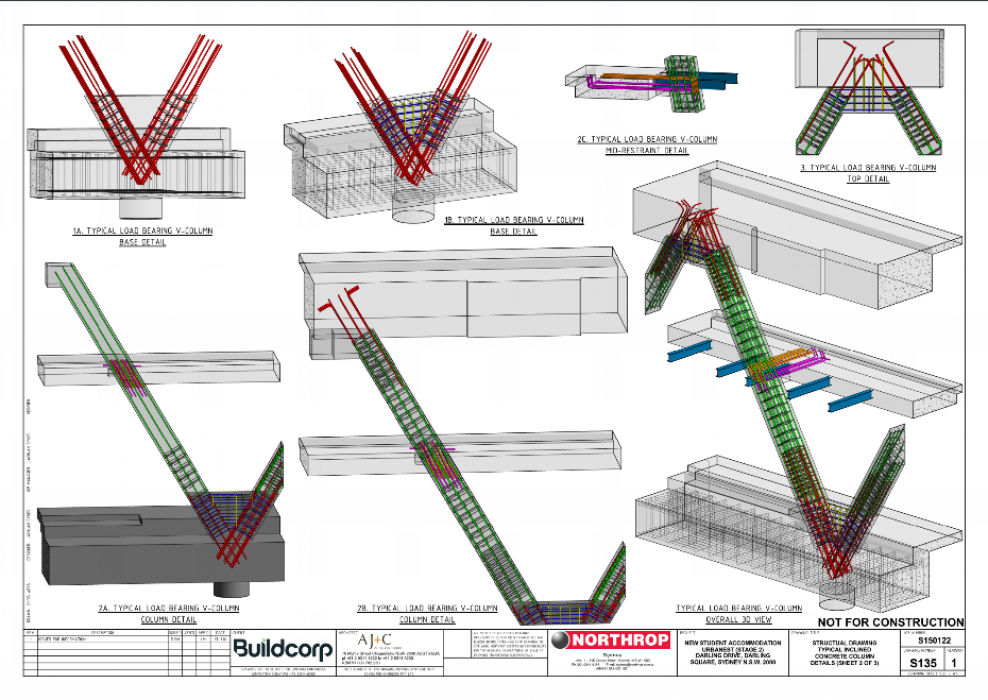

Northrop has significantly invested in exploring options of model reinforcement to determine the cause of reinforcement cost overruns, and find solutions to de-risk future projects. We focused on concrete columns and the first step was to embed all the design parameters into the column itself. This allowed all project stakeholders using a BIM viewer to select a column and have access to information such as concrete strength, vertical reinforcement, tie arrangement etc. The next step was to begin modelling column reinforcement within Revit with the goal of producing bending schedules and very accurate reinforcement tonnages. While this method is certainly possible it is impractically time consuming so another solution was sort. Trimbal’s Tekla is the ultimate 3D detailing package for steel and reinforcement detailing. Northrop Canberra has a precast detailing section that utilises Tekla, so a team from Sydney spent some time in Canberra utilising their software licence and modelling skills, to model and produce bar bending schedules for all concrete columns in the project. The information in the outputs from this model gave Buildcorp the confidence that the reinforcement they were ordering from the supplier was accurate in tonnages and arrangement eliminating wastage and time delays.