Turning architectural ambition into buildable reality

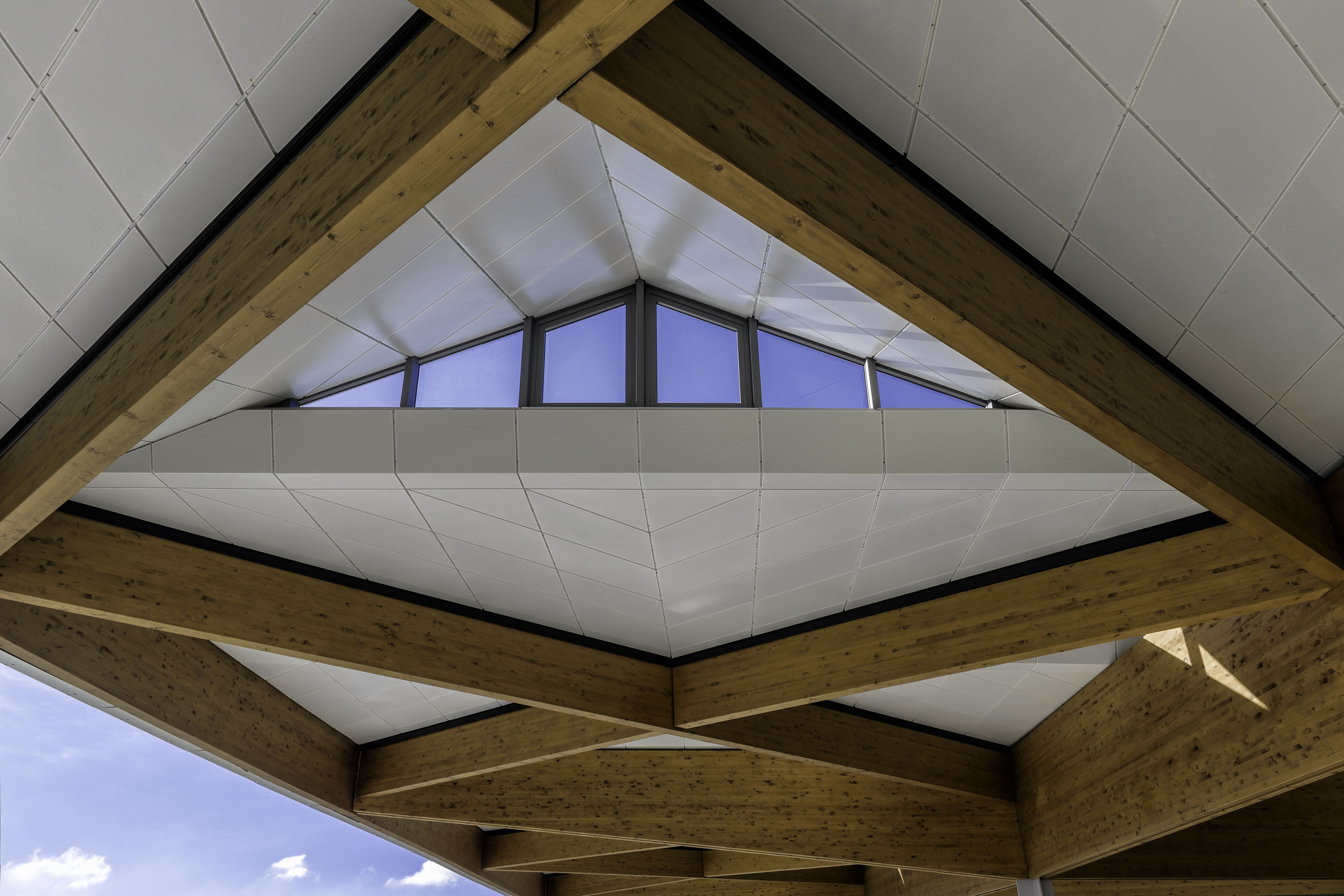

The new Sydney Fish Market is one of the most recognisable civic projects delivered on Sydney Harbour in decades. Designed by BVN in collaboration with 3XN, the project reimagines a working market as a major public destination, defined by a sweeping timber roof that responds to harbour conditions while creating a strong architectural identity.

For Northrop, the project represented a rare opportunity to apply specialist timber engineering at a scale and level of complexity not previously delivered in Australia. The timber roof design and certification was led by Dr Ali Habibi, Principal at Northrop, supported by a dedicated project team with deep experience in complex and engineered timber structures.

A roof that pushed beyond precedent

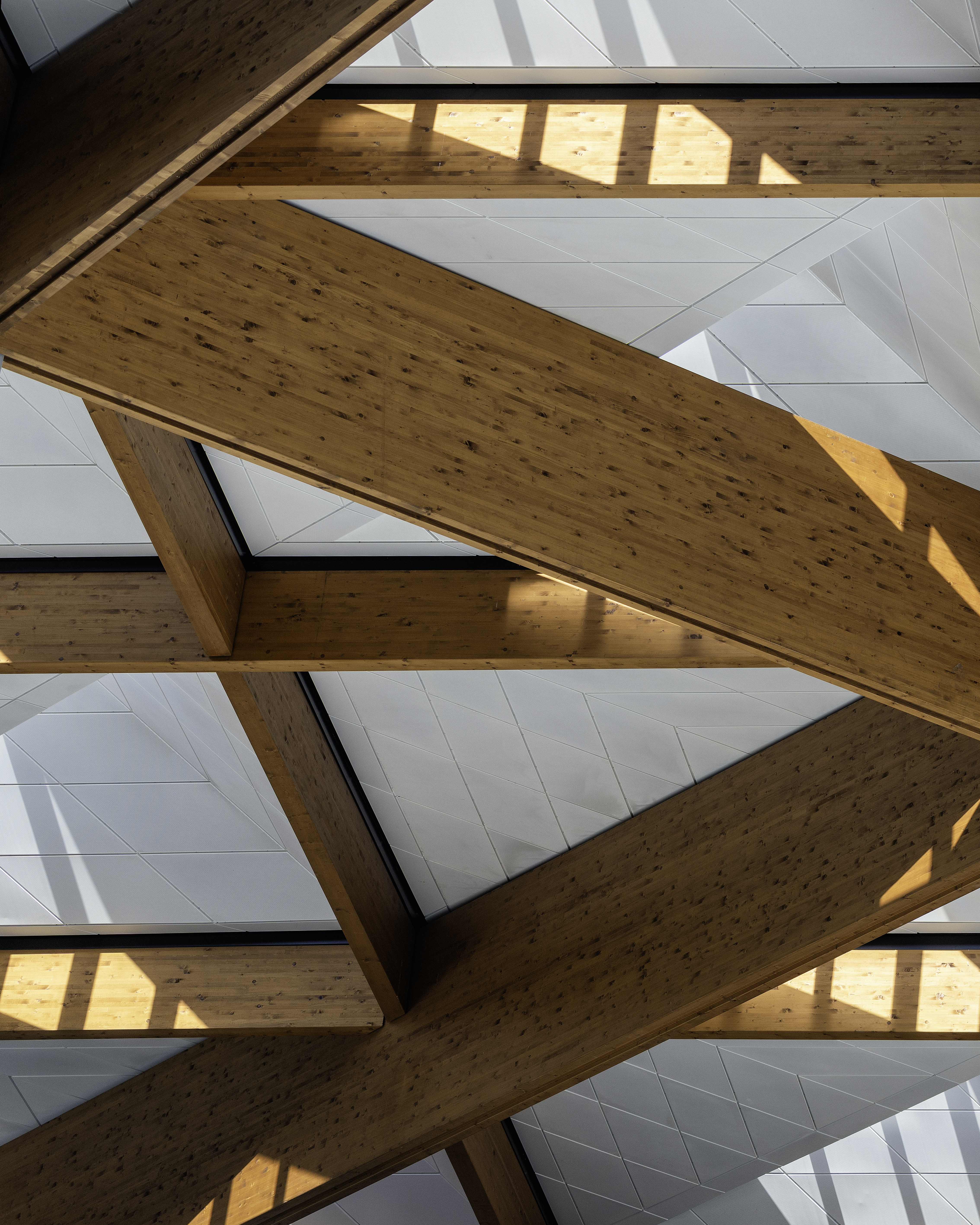

The roof structure spans up to 28 metres, with cantilevers of approximately nine metres, and is formed by a repeating system of timber members converging at complex nodes. In some locations, up to eight individual timber members meet at a single connection, creating significant structural, geometric and constructability challenges.

Compounding this complexity was the project’s coastal setting. Located immediately adjacent to the harbour, the roof is exposed to wind, salt-laden air and a highly variable microclimate. While steel would traditionally be considered for a structure of this scale, timber offered key advantages in durability and corrosion performance, provided it could be designed, detailed and protected correctly.

Independent design leadership and certification

Northrop was engaged as the timber structural engineer and independent design certifier for the roof, working under a tripartite agreement with Multiplex and Rubner, the specialist timber supplier based in Italy.

This commercial structure was deliberate. It ensured Northrop retained full independence as the certifying engineer, undertaking its own analysis rather than relying solely on supplier models. While Rubner led fabrication design, Northrop was responsible for independently designing and verifying the global structural behaviour of the roof, certifying compliance with Australian requirements, and coordinating with the concrete and steel engineers responsible for the substructure.

Designing for Australian conditions

A critical part of the project was translating European timber expertise into an Australian regulatory and environmental context. While the roof was designed using Eurocodes, Northrop led the development of a comprehensive performance solution to demonstrate compliance with the NCC, addressing areas not directly covered by prescriptive Australian standards.

Using engineering analytical software, Northrop developed an independent global model of the roof to assess gravity, wind and seismic actions. This allowed the team to interrogate load paths, test assumptions and refine member sizes and connection forces.

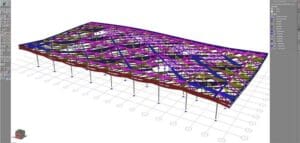

New Sydney Fish Market roof structural modelling. Click here to enlarge image.

Early modelling identified that initial load assumptions would have resulted in oversized members and visually intrusive steel connection plates, undermining the architectural intent. Through iterative analysis and close collaboration with the wider design team, Northrop was able to challenge and refine these assumptions, achieving a solution that satisfied structural performance requirements while maintaining the clarity and elegance of the timber geometry.