Macquarie University Central Courtyard Redevelopment

- Acoustics

- Electrical Engineering

- Hydraulic & Fire

- Mechanical Engineering

- Sustainability

The New Sydney Fish Market redevelopment is a defining addition to Blackwattle Bay, anchored by Australia’s largest timber roof. Designed by 3XN in collaboration with BVN and delivered by Multiplex, the project is anchored by a landmark timber roof that translates architectural ambition into a buildable, high-performance structure.

The New Sydney Fish Market redevelopment is a landmark civic project transforming Sydney’s working waterfront into a major public destination on Sydney Harbour. Designed by BVN in collaboration with 3XN, the project is defined by a sweeping timber roof that forms the architectural centrepiece of the precinct.

Northrop was engaged as the timber structural engineer and independent design certifier for the roof structure. The Northrop project team was led by Dr Ali Habibi, Principal and Structural Section Manager, responsible for independent structural analysis, certification and coordination across a complex, multi-party design and delivery environment.

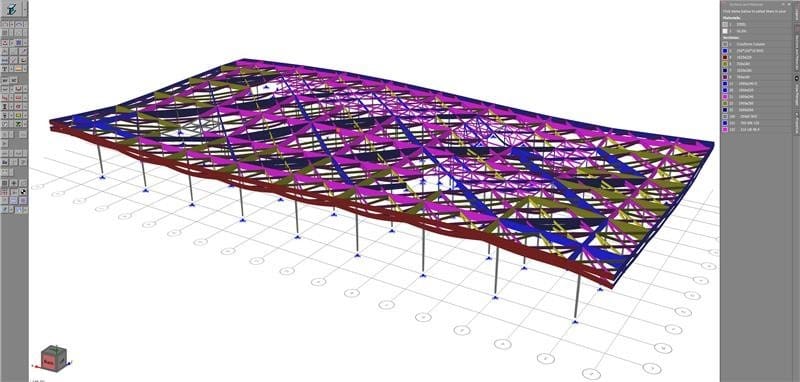

The timber roof spans up to 28 metres, with additional cantilevers of approximately 9 metres, and is formed by large timber members converging at sculpted nodes. In several locations, up to eight members connect at a single node, creating significant structural and constructability challenges. Located immediately adjacent to Sydney Harbour, the roof is exposed to strong winds and a marine environment, requiring careful consideration of durability and long-term performance.

Northrop was engaged under a tripartite agreement with Multiplex and Rubner, the European timber designer and supplier. This contractual structure ensured Northrop retained independence as the certifying engineer, while working closely with the broader design and delivery team.

A key aspect of the project was translating European timber design methodologies into an Australian regulatory context. While the roof was designed using Eurocodes, Northrop led the development of a performance solution to demonstrate compliance with the NCC.

Independent structural modelling was undertaken to assess gravity, wind and seismic actions, allowing load assumptions to be tested and refined to achieve an efficient structural solution aligned with the architectural intent.

Given the scale of the members and complexity of the connections, digital coordination alone was not sufficient. Northrop sent a member of the project team to Italy for three weeks to work face to face with Rubner’s engineering and fabrication teams. This allowed direct engagement around connection detailing, structural modelling and fabrication methodology, as well as a first-hand understanding of the timber product, factory processes and installation sequencing.

The in-person collaboration enabled design challenges to be resolved more efficiently than would have been possible remotely and informed refinements to connection detailing and construction sequencing.

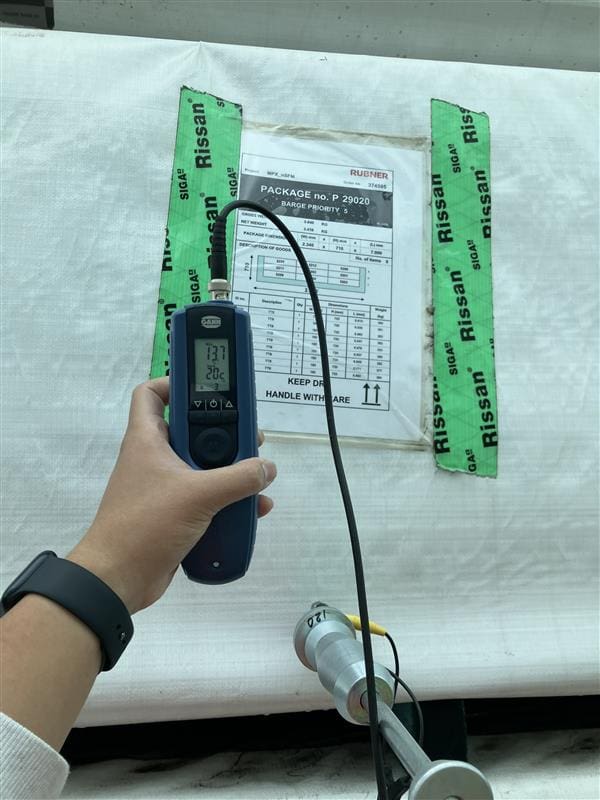

During construction, Northrop provided additional services including review of construction sequencing and extended moisture monitoring. This helped manage risks associated with prolonged storage of the timber elements prior to erection and supported the long-term performance of the structure.

The completed timber roof is one of the largest and most complex of its kind delivered in Australia. It demonstrates the value of early engineering involvement, independent verification and collaborative delivery in realising innovative, large-scale timber structures in demanding environments.

Image credit: Chris Cook Photography